Manufacturing

The workshop is used for production of conveyor belt wire ropes. It incorporates hundreds of efficient production lines .

This large-scale production means we can fulfill your largest of orders without delay.

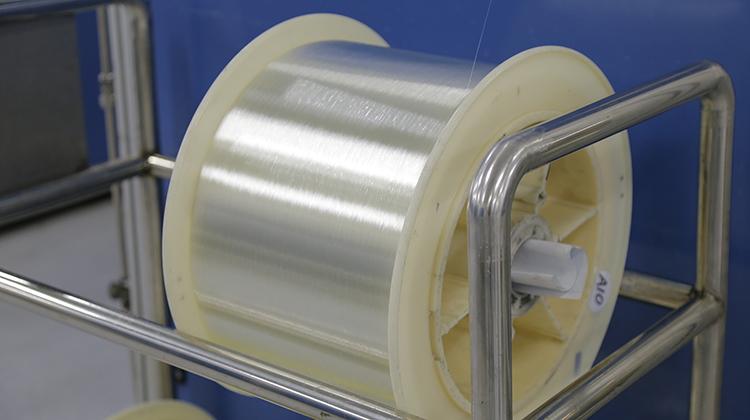

Seen here is the ultra-fine wire rope production workshop. The production capacity is designed to be 1,500 tons. These ropes are produced in diameters ranging from 0.26mm to 3mm. Once production has been completed, we will test the corrosion resistance of the surface of the wire rope in a salt spray test chamber. The maximum test duration reaches 312 hours.

When it comes to producing stainless steel wires and wire ropes, we only use top-grade stainless steel raw materials from Bao Steel, Zhejiang Ruipu, Fagersta, Nippon and other well-known companies. As a result, we guarantee our products will exhibit increased stability, high fatigue strength and strong corrosion resistance. The stainless steel manufacturing complex features an annual production capacity of 2,000 tons of stainless steel wire ropes and 30,000 tons of stainless steel wires.

The general purpose and specialty wire rope workshop is equipped with several dozen state-of-the-art production lines which can produce wire rope up to 110mm.

Our commercial wire base produces carbon steel wires from 0.5mm to 12.0mm for a number of different applications such as spring wire, ACSR wire, armoring wire, flexible sharft wire, structural wire, and so on. The heat treatment and phosphating line was imported from Belgium . It supports a yearly production capacity of 50,000 tons.

Fasten Group is the largest bridge cable manufacturer in china,

We own and operate a 2KM bridge cable production line

We Cover 70% of Our domestic market.

Our pre-stressed strand manufacturing base is equipped with 5 steel strand production lines, imported from Italy. The yearly production capacity reaches 200,000 tons. We manufacture the pre-stressed strands in sizes ranging from 7.9mm to 21mm.

Fasten Group has established a state-level enterprise technology center as well as a metal materials testing center. We have undertaken numerous national major projects which require advanced technology for technical support.

We also undertake the secretariats of the steel wire ropes subcommittee of the steel technology committee in SAC (SAC/TC 183/SC 12) as well as the steel wire ropes technology committee in the International organization for standardization (ISO/TC 105).

In addition, we have successfully established the “National Metal Wire Products Engineering Technology Research Center”.

A subsidiary of Fasten Group is focused on production of optical fiber preforms, communications grade optical fibers and specialty optical fibers. It owns core technologies and the intellectual property rights for optical fiber preforms. The annual production capacity of the communications grade optical fibers and optical fiber preforms has reached 8 million km.

Our generator sets are grouped into 3 major types, including the universal generator, truck-mounted generator and marine generator sets. The power of a single machine ranges from 3KVA to 3,000KVA. This equipment is widely applied in numerous industries which have a high demand for power supply reliability. Typical applications are found in energy and chemical industries; manufacturing industry; commercial real estate; communications industry; traffic logistics and many others.

Conveyor belt wire rope production workshop has several hundred efficient production lines which can produce 60,000 tons of products each year.

Wire rope production workshop

Wire rope production workshop  Wire rope production workshop

Wire rope production workshop

Ultra-fine wire rope production workshop has a large manufacturing capacity, whose designed manufacturing capacity arrives to 1,500 tons. And these ropes are of wide range of diameters-from 0.26mm to 3mm.

Ultra-fine wire rope production workshop

Ultra-fine wire rope production workshop

Finished ultra-fine wire rope warehouse

Salt spray test is delivered to check wire rope’s corrosion resistance performance. Our wire rope could even resist corrosion for 312 hours.

Regular spot check with salt spray testing equipment

Regular spot check with salt spray testing equipment Adhesion testing equipment

Adhesion testing equipment

Fatigue testing for aerial cable with atigue testing machine

When it comes to producing stainless steel wires and wire ropes, we only use top-grade stainless steel raw materials from BAOSTEEL, Zhejiang Ruipu, FAGERSTA, NIPPON and other well-known companies. As a result, we guarantee our products will exhibit increased stability, high fatigue strength and strong corrosion resistance.

Stainless steel wire and wire rope production base

Stainless steel wire and wire rope production base Raw material storage area

Raw material storage area Stock top-grade stainless steel raw material

Stock top-grade stainless steel raw material FASTEN GROUP corporates 12 stainless steel annealing lines

FASTEN GROUP corporates 12 stainless steel annealing lines Stainless steel annealing lines

Stainless steel annealing lines Our stainless steel production line is designed to produce stainless steel of 5,000 tons.

Our stainless steel production line is designed to produce stainless steel of 5,000 tons.  Stainless steel wire rope production line

Stainless steel wire rope production line

Stainless steel wire rope production line

FASTEN GROUP adopts enterprise resource planning (ERP) system, which could be used to track business resources. As a result, it highly assures the traceability of our manufacturing.

Huge finished product warehouse

Huge finished product warehouse

Packed spool coil is quite heavy, and the largest up to 1 ton.

Tensile testing for stainless steel wire

Tensile testing for stainless steel wire Torque testing for stainless steel wire

Torque testing for stainless steel wire

Raw materials’ chemical composition analysis with spectrum analyzer

Spectrum analyzer for raw material

Spectrum analyzer for raw material

The workshop could produce 100,000 tons of large parallel lay wire ropes each year.

The workshop could produce 100,000 tons of large parallel lay wire ropes each year.  Large-scale parallel lay wire rope production line

Large-scale parallel lay wire rope production line

Large-scale parallel lay wire rope manufacturing equipment

Large-scale parallel lay wire rope manufacturing equipment Close-up view for large-scale parallel lay wire rope manufacturing equipment

Close-up view for large-scale parallel lay wire rope manufacturing equipment

Steel wire rod drawing and annealing line with annual production capacity of 70,000 tons

Steel wire rod drawing and annealing line with annual production capacity of 70,000 tons Finished wire rope product warehouse

Finished wire rope product warehouse

This is raw material warehouse for steel wire and wire rope. These materials are quite enough for future manufacturing.

Huge steel wire warehouse

The hot-dip galvanizing line is mainly used in the production of conveyor belt wire ropes, fitness equipment ropes and aerial cables. Besides that, it could also be used in wire drawing.

Hot-dip galvanizing line

Hot-dip galvanizing line

The phosphating line for heat treatment of steel wires is imported from South Korea. It supports a yearly production capacity of 20,000 tons.

Water cleaning and pickling in steel wire production line

Water cleaning and pickling in steel wire production line  Steel wire’s water cleaning

Steel wire’s water cleaning  Zinc-coating testing for quality control

Zinc-coating testing for quality control Tensile testing

Tensile testing

Bridge cable production line

Bridge cable production line Stay cable production line

Stay cable production line

Stay cable production

Stay cable production  Packaging for finished stay cable products

Packaging for finished stay cable products

Suspension cable products

Anchor grouting begins right after suspension cable products have been completed.

When it comes to producing pre-stressed strand, we only use top-grade raw material from SHAGANG GROUP, ZENITH, YONGGANG GROUP and other well-known companies. As a result, we guarantee our products will exhibit high quality.

Raw material storage area

Raw material storage area

Our pre-stressed strand manufacturing base is equipped with 5 steel strand production lines, imported from Italy. The yearly production capacity reaches 200,000 tons. We manufacture the pre-stressed strands in sizes ranging from 7.9mm to 21mm.

Pre-stressed strand production lines introduced from Italy

Pre-stressed strand production lines introduced from Italy

Complete process flow-Surface treatment for raw materials

Surface treatment for raw materials

Surface treatment for raw materials Steel strand production line

Steel strand production line  Products ready for packaging

Products ready for packaging Packaging for finished products

Packaging for finished products

Indoor finished product warehouse with enough stock

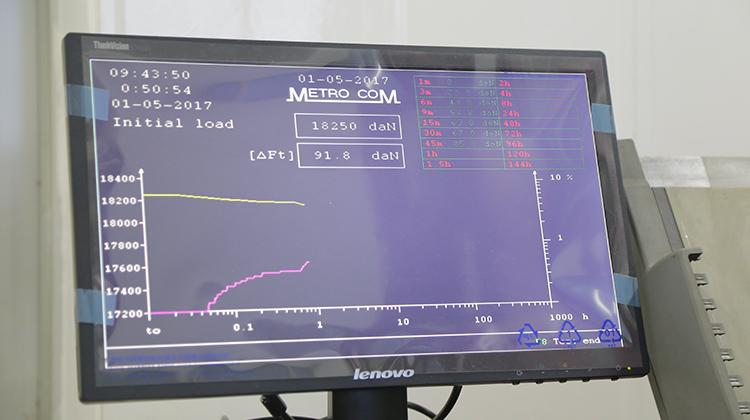

Stress relaxation test for steel strand with horizontal stress relaxation tester

Vertical stress relaxation tester introduced from Italy

Parameter data collected during the test

MCVD lathe is mainly used to produce special optical fiber preforms with vapor deposition.

A subsidiary of Fasten Group is focused on production of optical fiber preforms, communications grade optical fibers and specialty optical fibers. It owns core technologies and the intellectual property rights for optical fiber preforms. Besides that, not only does it possess sophisticated MCVD (modified chemical vapor deposition) and OVD (outside vapor deposition) methods, it also designed and developed the key equipment for manufacturing optical fiber preform - OVD equipment. With these advanced technologies and machines, it finally invented large-sized low-water peak optical fiber preform. Moreover, its annual production capacity of the communication-grade optical fibers and optical fiber preforms has reached 8 million km.

(modified chemical vapor deposition) lathe

(modified chemical vapor deposition) lathe

OVD lathe is mainly used to manufacture the mandrel and the soft jacket on the finished optical fiber preform - key instruments in manufacturing optical fiber preform. These instruments are patented by our company. Besides that, we also own the manufacturing capacity for fabricating large-sized low-water peak optical fiber preform.

OVD lathe (Outside vapor deposition)

OVD lathe (Outside vapor deposition)

The machine is used to connect handles on finished products. After connecting handle on the finished product, the finished product could be fixed on the wire drawing machine with the help of fixture. Wire drawing starts right after the fixing process.

Finished product machining lathe

Finished product machining lathe

Fiber drawing tower is mainly used to draw the preform into optical fibers. FASTEN GROUP corporates more than ten wire drawing lines, which supports a yearly production capacity of 8 million km. It could produce sensing polarization-maintaining optical fiber for 2,500km, and that of 980nm fiber optic coupler is of 2,500km.

Fiber draw tower

Fiber draw tower

In shielding process, there is an exterior force exerted on optical fiber. The force might be too large for some parts of the fiber, and there will be a breaking in these parts. The process is to remove these parts, and ensures high mechanical performance for optical fibers. Fibers are twisted on a device. And rewinding process is to rewind some of them on another device in a given rate. In this way, the fibers are separated into different devices. Or we could just alter the rewinding quality of the fibers. These two methods could renew fibers attenuation. Our rewinding workshop could well meet the manufacturing need.

Shielding and rewinding workshop

Shielding and rewinding workshop

In dyeing workshop, optical fibers are coated with color ink. Then UV curing is delivered on the fibers, which will generate colorful fibers. It could color 1,600m-ribbon in a single minute.

G652D communication-grade optical fiber after drawing process

G652D communication-grade optical fiber after drawing process Optical fiber dyeing workshop

Optical fiber dyeing workshop

With the help of resin, multi-fiber could be merged into an array of adjacent fibers to create a multi-filament ribbon. The ribbon is of different standards, ranging from 4-24 fibers. Then they will be used in plastic sheathing process.

Multi-fiber merging line

Multi-fiber merging line

The workshop is mainly used to deliver testing for optical fiber’s optical performance, transmission performance, dimensions, parameters, and mechanical properties. It is equipped with diverse inspection equipment, such as optical time domain reflectometer, PK-2200 spectral attenuation bench for spectral attenuation measurements, CD400 and so on.

Testing workshop for optical fiber

Testing workshop for optical fiber

An area for optical performance monitoring and transmission performance testing

Features:

Products are well organized in the warehouse.

All the products are safely stored and well packaged in the warehouse, with clear and undamaged logo.

Fast and efficient delivery

Delivery by sea or air is available.

No-sidewall warehouse

No-sidewall warehouse

Fasten Group Imp. & Exp. Co., Ltd.

Add.: No.165 Middle Chengjiang Road, Jiangyin City, Jiangsu Province, China

Post Code: 214434

Tel.: +86-510-86907777-8203

Cell: +86-13915239039

Fax: +86-510-86111924

E-mail: gu_xianghua@chinafasten.com